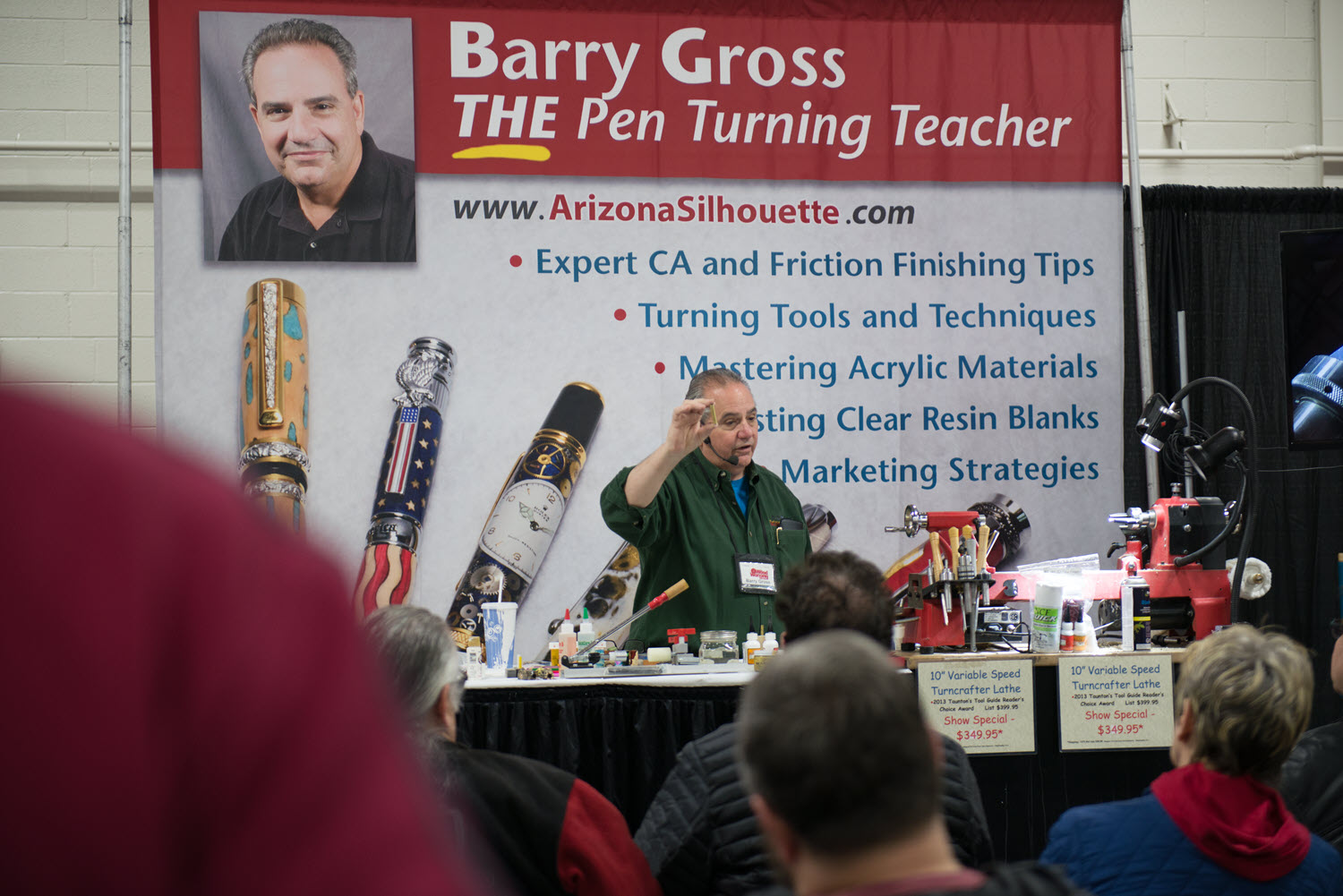

Barry Gross

Master Pen Maker, Published Author & Instructor/Educator

Barry has been working with wood for over 45 years and is an author of 6 books and 2 DVD’s on turning and pen making and has over 60 articles published in many wood working magazines including Fine Wood Working and Woodturning Design Magazine. He has demonstrated his methods on pen making at AAW symposiums and many turning clubs throughout the country. In addition, he is an instructor at Arrowmont School of Arts & Crafts and The Marc Adams School of woodworking.

Barry Gross’ 2024

Seminars included with general admission

Pen Making – “Start to Finish”

(Friday: 12:30 -1:15 PM | Saturday: 10:45 – 11:30 | Sunday 10:30 – 11:15)

- Pen Blank Material Selection

- Drilling & Gluing Your Material

- Squaring Your Pen Blank

- Tool Selection – Carbide / High Speed Steel

- Turning & Sanding

- Applying “CA Glue” As A Finish

- Pen Blank Assembly

“Kitless Pen Making – Part 1 Lower Barrel, Part 2 Upper Barrel, Part 3 Nib Section”

(Part 1 Friday: 2:00 – 2:45 | Part 2 Saturday 12:00 – 12:15 | Part 3 Sunday 12:00 – 12:45)

- Items Needed

- A chuck for the head stock, (4 or 3 jawed chuck, drilling chucks)

- Jacob’s Chuck for tail stock

- Digital calipers and chamfering tool

- Taps & dies specific to the pen you will be making

- Kitless mandrels for upper, lower and nib sections

- Drill bits specific to the pen you will be making

- Turning tools of choice

- Acrylic stock 8” to 9” in length

- Acrylic Buffing System & sanding pads

- First check your lathe – point to point

- Cut the rod into three sections:

- Lower barrel 3 ½”

- Upper barrel 2 3/4”

- Nib Section 1 5/16”

- Chuck the lower barrel into the head stock chuck and proceed with making the lower barrel.

Casting Your Own Pen Blanks

(Friday: 3:15 – 4:00 | Saturday 2:30 – 3:15 | Sunday 1:15 – 2:00)

- Label Casting (pictures)

- Acrywood (wood & acrylic combination)

- Material Selection:

- Polyester Resin

- Alumilite

- White – 2 ½” minute working time

- Demold 15 minutes

- Clear – 7 minute working time

- Demold 90 minutes

- Clear Slow – 12 minute working time

- Demold 3 hours